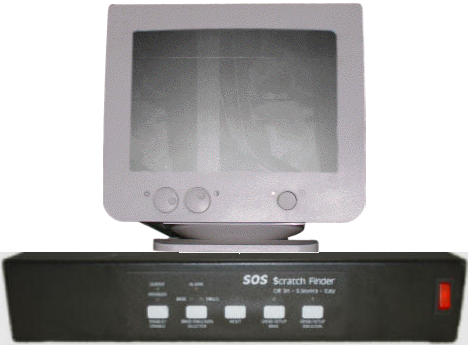

Scratch Finder Automatic Scratch Detector Cat. PH116-B

Scratch Finder Optical Unit Cat. PH116-C

Cine-Film Processing requires a fine anti-scratch supervision!

If during the film processing a film scratching accident occur, in the standard commonly adopted procedure, only a following checkup will enhance and reveal the defects and any subsequent countermeasure already costs a lot in terms of lost raw stock material. With the Scratch Finder it is possible to reveal and optionally even to acoustically alarm the presence of a scratch on the film surface so to draw the operator attention on the problem so to activate the necessary proper countermeasures. This check can be done directly on the film running just after the drying cabinet. Its installation can be done on virtually any model of processor on the market.

- The SF Optical Unit (Cat. PH116-C) enhances with infrared vision onto the monitor screen any surface fault like scratches, dust, etc…

- The SF SOS Automatic Scratch Detector (Cat. PH116-B) identifies the scratch and shows it clear and enlarged onto the monitor screen emitting an acoustic alarm.

- The SF SOS Automatic Scratch Detector (Cat PH116-B) can be easily set to detect any scratch-type, even of few microns.

- The operator can immediately evaluate the entity of the scratch from the monitor screen and intervene to remove its cause.

- Easy to assemble on any type of cine-film processor, is perfectly suitable for B/W and colour, positive and negative film-processing.

Worldwide used profitably by many top cine-processing laboratories (front end as well as release print labs).

Scratch Finder ensures a high standard quality of processing reducing waste materials.

DIMENSIONS:

- Length 350mm

- Width 360mm

- Height 70mm

- 5mt Standard Cable

- (between Optical and SOS units)

SPECIFICATIONS:

- Feeding power supply 220/110 Volt

- Maximum power consumption 10/20 Watt

- Environmental operating conditions :

- Temperature +/- 40°

- Humidity 90% without condense

SF Positive Optical Unit (Cat. PH116-C)

SF SOS Automatic Scratch Detector (Cat. PH116-B)

FSC FilmStroboChecker Digitally Evolved (Cat. CINE4D)

Easy to fit on any 35/16 cinema film processor (negative and positive), ensures non stop quality monitoring during all film processing phases.

A perfectly clear vision is provided by a special led backlight-based video strobo system that visualizes, while processing, the total film surface, scene and perforations up to the border line without flickering at any transport speed through a 1032*778 CCD sensor.

Possibility to crop into the film details such as perforations, analog & digital sound tracks (Dolby-DTS-Sony) to better control the standard quality of processing.

The negative-film, black and white or colour, is displayed on the monitor in positive with the possibility to control the colour (separate gamma and gain RGB), to better enhance otherwise invisible defects, including pressure marks typical of high sensitive film.

The zooming capability allows observation in real time, during the processing operations, of little details “as through a lens”, to quickly and easy find dust, blemishes, damage perforations, scratches or processing problems. The SF Analogue Optical Unit, made-up of a special CCIR and Infrared 950nm lighting source, enhances any surface fault during all processing phases.

Also available on option, the SF SOS Automatic Scratch Detector (Cat PH 116-B) to identify and alert the operator with an acoustic alarm in case of a scratch.

The sensor group containing the two CCD (colour and b/w), with their respective light sources, is ready to be easily fixed after the dryer of any processor.

FSC FilmStroboChecker is an impressive quality checking system to guarantee a high quality standard level to the whole negative and positive processing line

Computer, Strobo and optional PH116B

BW monitor

The Optical Scratch Finder displays any scratch otherwise invisible…

Main Plate

WHAT’S NEW ON “DIGITALLY EVOLVED”

The necessary shift of the FSC into the digital video environment, has brought some good advantages for an easy, flexible and more intuitive use of the equipment.

FSC Digitally Evolved comes with a PC that substitutes the previous analogue video frame memory system and gives a better smoothness to the video flow.

FSC Digitally Evolved come with an integrated gamma and gain separate RGB control for a more precise colour profiling on the different film masks.

The new Strobo unit that equips the FSC Digitally Evolved gives a new frame centring control that allows an easier scene frame tuning with just “one push” of a button

SF SOS Automatic Scratch Detector (Cat. PH116-B)

SF SOS Automatic Scratch Detector (Cat. PH116-B) connected to FSC FilmStroboChecker emits an acoustic signal for any identified scratch, showing it clearly on monitor screen during processing.

Its logic it is based on the video analisys of the signal coming from the Optical Scratch Finder unit. Through a fields comparison of the video signal, it is possible to detect all linear scratches so to generate a sound alarm useful in alerting the operator for the problem in progress.

The logic sensitivity can be freely adjusted according to the laboratory necessities and film running speed.

Autochecker 35 DLX (Cat CINE9) – Autochecker 16 DLX (Cat CINE9)

The new Autochecker CINE 35 DLX has been specifically designed to satisfy the requirements of the Top of the Front End Labs for maximum automation and quality control in order to ensure always the maximum level in negative processing.

This advanced technology device automatically identifies and stops immediately any fault or phisical condition of the film potentially unsafe for a correct development.

Autochecker 35 DLX

Autochecker 16 DLX full option

Autochecker remarks with a beep border tears, broken perforations, overturned emulsion and any other of the film damages:

Cuts of any dimension on the edges between perforations (very dangerous because it can occur a breakage of the film during processing phase).

Cuts of any dimension between perforations and edges.

Damaged perforations; and in this case the operator can decide how many perforations must be broken to stop the film.

Updown emulsion (sometimes happens when the film has been spliced wrongly.

Scratches, abrasions or folds between perforations on both sides of the film (scena area).

Blemishes, bad splices, adhesive tapes, staples or any anomaly onto scena area.

Once found and stopped the fault is positioned exactly over the splicer matrix for quick and easy film mending.

Sensor Heads

- secure film-loading system

- easy darkroom operations

- 200 feet/min checking-speed

- CPU controlled tension

- up to 2000 feet capacity spool

- film-splicing unit M3 35 DKR

- film-mending unit M3 35 2FR

M3 35mm Darkroom

M3 35mm Positive 2Frames